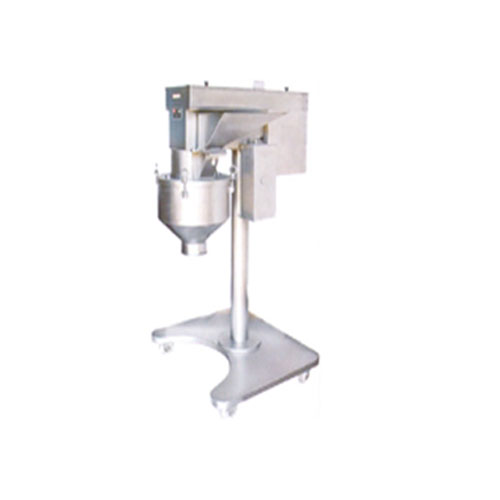

GMP's Multi Mill is used for wet and dry granulation, pulverization etc. The Unit consists of Stainless Steel Hopper, Processing Chamber with Beater Assembly, Motor, DOL Starter, Variable Speed Pulley, Screen and Sturdy Body. It operates on the principle of variable force swing beaters having both knife and impact edges rotating within a selected screen to get the required size reduction. Material fed in the hopper, goes down to the processing chamber where it moves to the periphery and passes through the screen radially and tangentially. Finally the processed material gets collected in the container which is kept below the processing chamber. Output and Quality of the final product depends on three key factors like Shape of Beaters (Knife/Impact Edges), Speed and Screen.

Salient Features :

Optional :