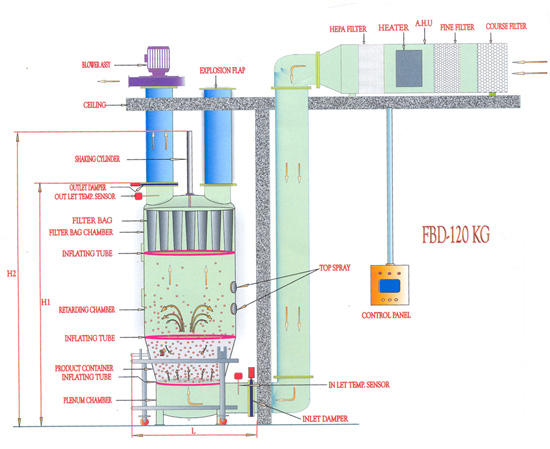

GMP Fluid Bed Dryer with latest improved design makes this unit a truly versatile for Pharmaceutical, Food, Dyestuff & Chemical industries. Our Fluid Bed Dryer is capable of drying materials in any forms like granular, powder or crystalline. Afluidized bed of solid particles with a stream of air passing up-ward through the particles at a rate great enough to set them in motion. As the air travels through the particle bed, the particles behave as boiled water. The active motion creates the potential for improved mixing and results an isothermal property. In a bubbling fluidized bed, no temperature gradient exists within the mass of the fluidized particles. Because the temperature and volume of the air can be precisely adjusted, the process achieves fast heat transfer making it very efficient, yet gentle on the product. Our product precisely maintains moisture content up to 20% which is ideal for pharmaceuticals and chemicals .

Salient Features :

Contrtol Panel :

Technical Specifications :

| MODEL | CF10 | CF30 | CF60 | CF120 | CF150 | CF200 | CF250 | CF300 |

| Bowl Volume (Liters) | 35 | 110 | 200 | 425 | 500 | 625 | 780 | 925 |

| Batch Size (Kgs) | 10-15 | 30-40 | 60-75 | 120-150 | 150-180 | 200-230 | 250-280 | 300-330 |

| Heating Load : (kw) For Electrical Heating | 6 | 18 | 36 | 54* | 60* | * | * | * |

| Approx. steam Consumption Kgs/hr. (Steampressure 3.5 kg / cm2) | 15 | 25 | 50 | 100 | 130 | 170 | 200 | 250 |

| Motor (H.P.) | 2 | 5 | 10 | 15 | 20 | 20 | 25 | 30 |

| Drying Temp C* | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

| Height H1 (Approx) mm | 1600 | 1900 | 2200 | 2550 | 2600 | 2800 | 3000 | 3100 |

| Height H2 (Approx) mm | 2000 | 2550 | 3000 | 3500 | 3500 | 3900 | 4000 | 4200 |

| Width (Approx) mm | 1050 | 1400 | 1550 | 1800 | 1850 | 2000 | 2100 | 2150 |

| Lenth (Approx) mm | 800 | 1250 | 1500 | 1700 | 1700 | 2000 | 2100 | 2200 |